Enhancing Mechanical Strength and Reducing Protrusion in Clinched Joints: A Comparison of Reshaped Clinching Methods

DOI:

https://doi.org/10.37934/aram.137.1.4457Keywords:

Clinch-rivet, reshaped clinching joint, mechanical strengthAbstract

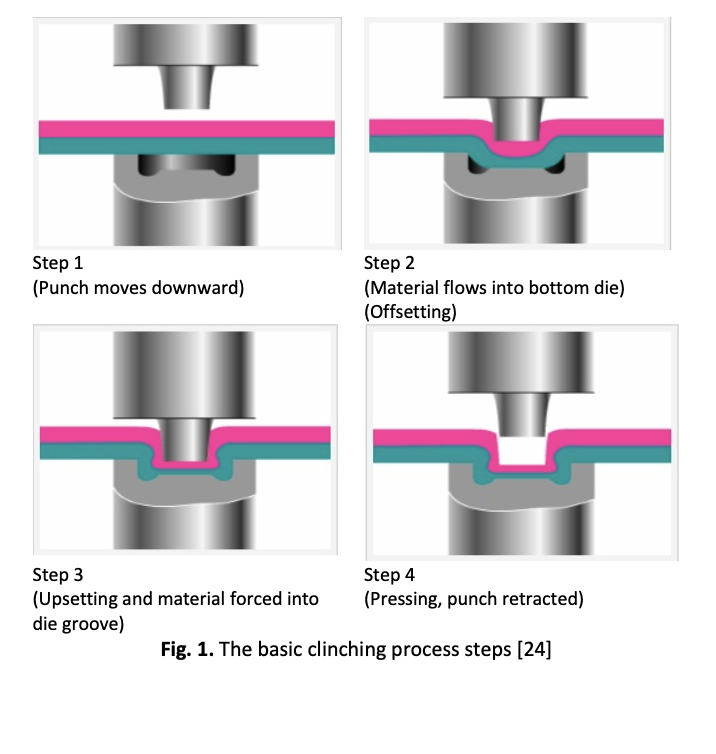

In recent years, mechanical clinching technology has gained increasing attention. However, the significant protrusion at the clinched joint could restrict its potential applications. This study investigates the mechanical strength of reshaped clinched joints and clinch rivets, addressing the common issue of protrusion in conventional clinching. By reshaping the protrusion to reduce its height, the strength and integrity of the clinched joints are enhanced. The experimental setup includes a fixed die and two sets of flat surface dies, using aluminium alloy AL5052 sheets. Results indicate that reshaped clinching significantly improves mechanical strength compared to conventional methods. Additionally, the tension-shearing strength of the reshaped joints shows a slight increase. Key findings reveal that reduced protrusion height correlates with increased joint strength and reshaping with a rivet provides superior joint strength compared to both conventional clinching and normal reshaping. The study also highlights the impact of metal thickness on joint strength, demonstrating that varying thicknesses lead to improved outcomes. These insights underscore the importance of punch depth control, reshaping strategies and material thickness in optimizing clinched joint performance, showcasing the potential of reshaping techniques in enhancing manufacturing processes.

"SHARE YOU KNOWLEDGE FOR A BETTER TOMORROW"

"SHARE YOU KNOWLEDGE FOR A BETTER TOMORROW"