Sustainability Integration and Parameter Optimisation in Advancing Plastic Injection Moulding

DOI:

https://doi.org/10.37934/aram.137.1.8295Keywords:

Plastic injection moulding, sustainability integration, process parameter optimisationAbstract

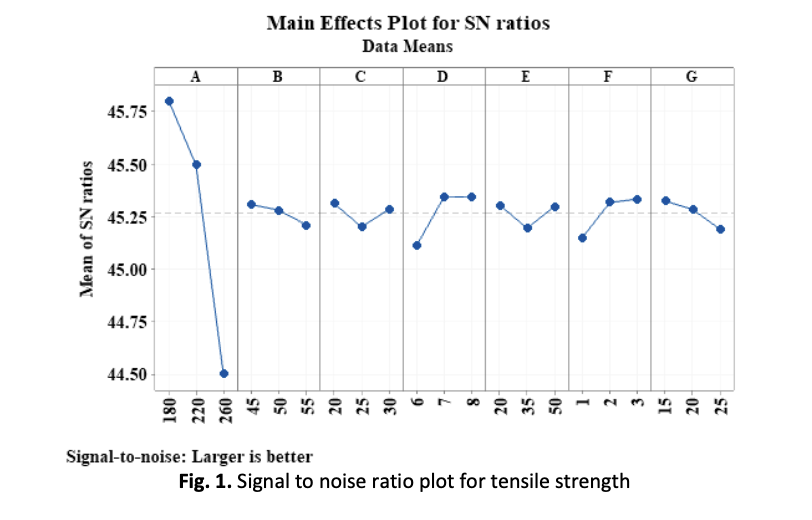

Injection moulding is a widely used method for manufacturing plastic components, with the quality of the final product depending on various process factors managed throughout the procedure. Integrating sustainable manufacturing practices is crucial for mitigating ecological impacts while maintaining product excellence. Manufacturers need to balance product quality, procedural effectiveness and environmental impact by evaluating how each parameter affects the product's quality and ecological footprint. While many focus on optimizing process parameters, fewer consider integrating sustainability competency, which also affects parameter performance. This study aims to advance understanding by conducting experiments and analyses on these factors' influence on product quality. The incorporation of sustainability competency aims to empower individuals and entities to make informed choices that align with environmental, societal and economic factors for a more sustainable and accountable future. The optimised model, with an error of less than 1%, quantifies the competency value bridging mechanical properties and comprehensive competency by integrating attitudinal factors. Parameter selection through Design of Experiments (DOE) and expert elicitation method contribute to this integration. Evolution from the foundational to the proficient model includes operational team and sustainability competency descriptors, providing context for innovation and knowledge creation highly valued by employers and stakeholders in a productive and streamlined setting.

"SHARE YOU KNOWLEDGE FOR A BETTER TOMORROW"

"SHARE YOU KNOWLEDGE FOR A BETTER TOMORROW"